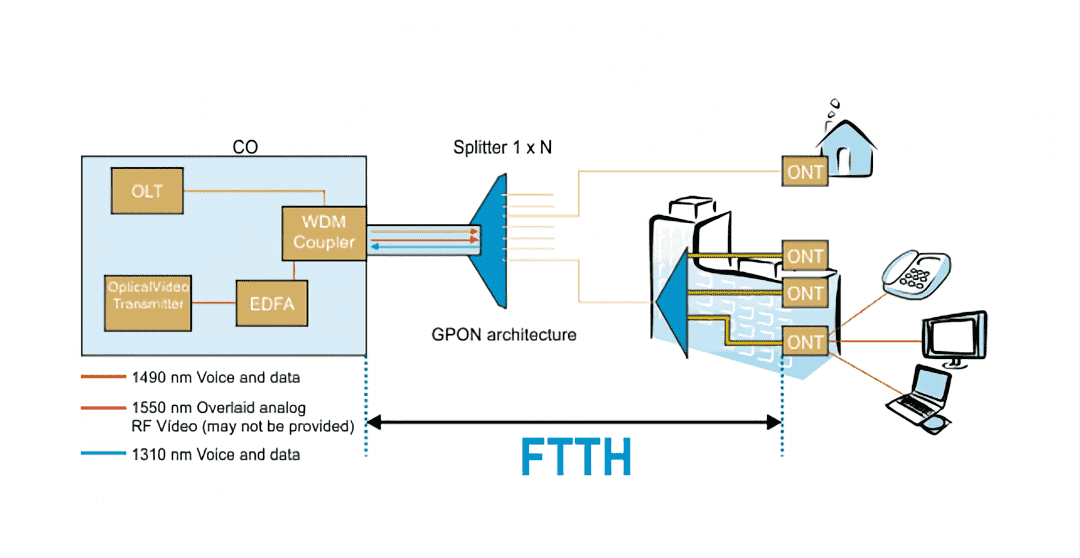

Whether it is an enterprise network or a home network, fast and reliable Ethernet is an inevitable requirement. With the maturity and popularization of 10G Ethernet technology in the commercial field, the cost of 10G network deployment has been greatly reduced. Because of this, some home users have begun to consider upgrading the previous 1G optical fiber home network to 10G, but for home users , 10G optical fiber network is a new field.

What equipment is needed when deploying 10G home optical fiber network?

For 10G home optical fiber networking, home 10G switches, routers and wireless access points (APs) are essential components. Depending on the requirements, devices such as network servers, 10G network cards, PoE switches, and IP cameras may also be required in the home network.

How to choose the best equipment for 10G home fiber optic network?

Home Network Switch

For 10G home fiber optic network, you may need 10 Gigabit network switch and PoE switch

1. Function and performance

Network switches have many functions, especially managed network switches. However, for home network switches, it is not necessary to choose a network switch that supports all functions, but choose to support basic functions, such as QoS, VLAN, and security. At the same time, you can also consider the stacking function and power over Ethernet function. The stacking function can bring higher flexibility to the network. If you want to upgrade the network later or need to add more network devices to the network, stacking multiple switches may be the most effective and economical solution, because it can be used in Meet your needs without changing the original network architecture. The Power over Ethernet function can supply power to PoE devices. If you need to deploy PoE devices such as IP cameras in your home network, it is recommended that you choose a switch that supports Power over Ethernet (PoE switch or PoE+ switch).

In addition, power consumption and capacity are also factors to be considered. Since the larger the switching capacity, the stronger the data exchange capability of the switch, in order to ensure the stable and reliable operation of your home network, it is recommended to choose a network switch with a larger switching capacity. At the same time, it is necessary to choose a fanless network switch for home networking, because the fanless network switch is basically noiseless and helps to reduce system power consumption.

2. Port

Generally, the port types of home network switches include electrical ports (that is, RJ45 ports) and optical ports (such as SFP/SFP+ ports). Among them, electrical ports are generally connected with Cat6 network jumpers, while optical ports generally need to be used with optical modules and fiber jumpers, such as SFP+ ports are generally used with SFP+ optical modules and LC duplex fiber jumpers. . In addition to considering the port type, the number of ports on the home network switch is also a factor that needs to be considered. If your network does not need to connect many network devices, generally speaking, an 8-port or 12-port 10G switch can meet the demand; but If you need to connect a lot of network devices or the network scale will expand in the short term, it is recommended that you choose a 24-port or 48-port 10G switch. All in all, all choices are based on your actual network needs.

3. Cost

Because the cost of the electrical port is lower than that of the optical port, the cost of the electrical port (ie RJ45 port) network switch is generally lower than that of the optical port network switch. Managed network switches are also more expensive than unmanaged network switches. After determining the type of home network switch, you can compare the home network switches provided by different suppliers on the market and choose the most cost-effective one.

Home Router

A router is an essential device that connects your home network to the Internet. Compared with home network switches, the choice of home routers is much simpler. First of all, you should contact your Internet Service Provider (ISP) or check your account details directly to obtain your bandwidth rate and see how high a rate router is needed to handle the bandwidth rate. Considering that you are now cabling your 10G home fiber optic network, the router you choose should have at least one SFP+ port. Secondly, you need to determine the type of router you need. Currently, routers are divided into wired routers and wireless routers. Although wireless routers can provide both wireless or Ethernet connections, their wireless WiFi signal coverage is limited, and they are usually more expensive than wired routers. Therefore, if your home network covers a large area, considering the cost and the stability of the connection, it is recommended that you give priority to a wired router (which can be used with a wireless access point).

Home Wireless Access Point

A wireless access point is essential if you want your wireless devices to be able to access the Internet. When choosing a wireless access point, you must first confirm several questions: How many wireless devices do you have? What is the maximum area that a WiFi signal needs to cover? How far can your chosen wireless access point cover? After confirming these questions, you can determine how many wireless access points need to be purchased, so that you can avoid choosing too few or too many wireless access points.

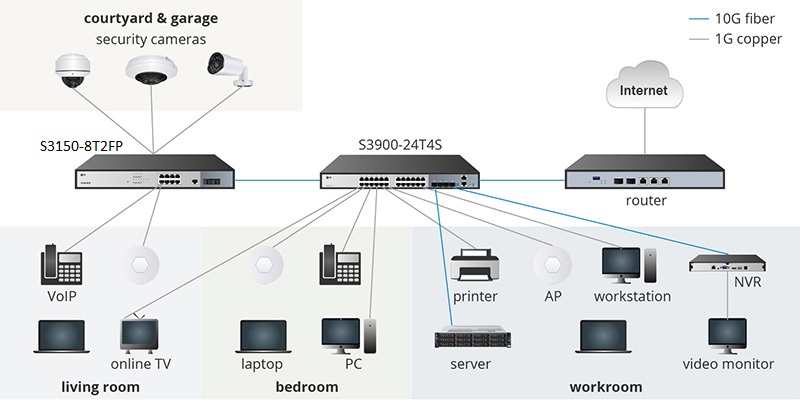

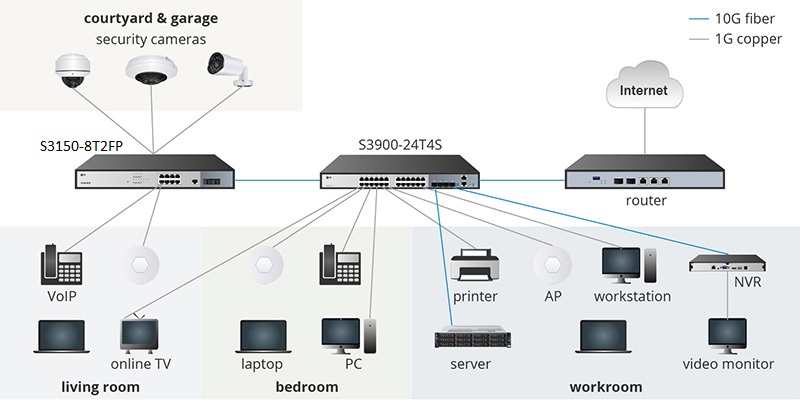

After selecting the network equipment, it is time to deploy the 10G home optical fiber network. A typical 10G home optical fiber network deployment diagram is as follows. There are many network devices in the whole house. After calculating the connection lines, the 24-port 10G switch is used as the core switch in the home network. Among them, the 24 ports of the 10G switch The ports are connected to most terminal devices, and the 4 SFP+ optical ports of the 10G switch are connected to PoE+ switches, routers, network video recorders (NVR) and servers. As for PoE devices in yards, garages, etc., just connect them to an 8-port PoE+ switch.