LCD Splicing Screen vs. LED Screen Differences and How to Choose

In today's world of digital display screen, choosing the right technology for your needs can be challenging. This blog will help you understand the differences between LCD splicing screens and LED screens, focusing on the advantages of LCD splicing screens to help you make an informed decision.

What is a Splicing Screen?

A splicing screen, or video wall, is a large display created by combining multiple smaller screens. These screens, which can be either LCD or LED panels, are connected and configured to work together as a single, cohesive display. Splicing screens are commonly used in various settings, including command centers, control rooms, advertising spaces, and public displays, providing flexible configurations and high visual impact.

What is Seamless Splicing Technology?

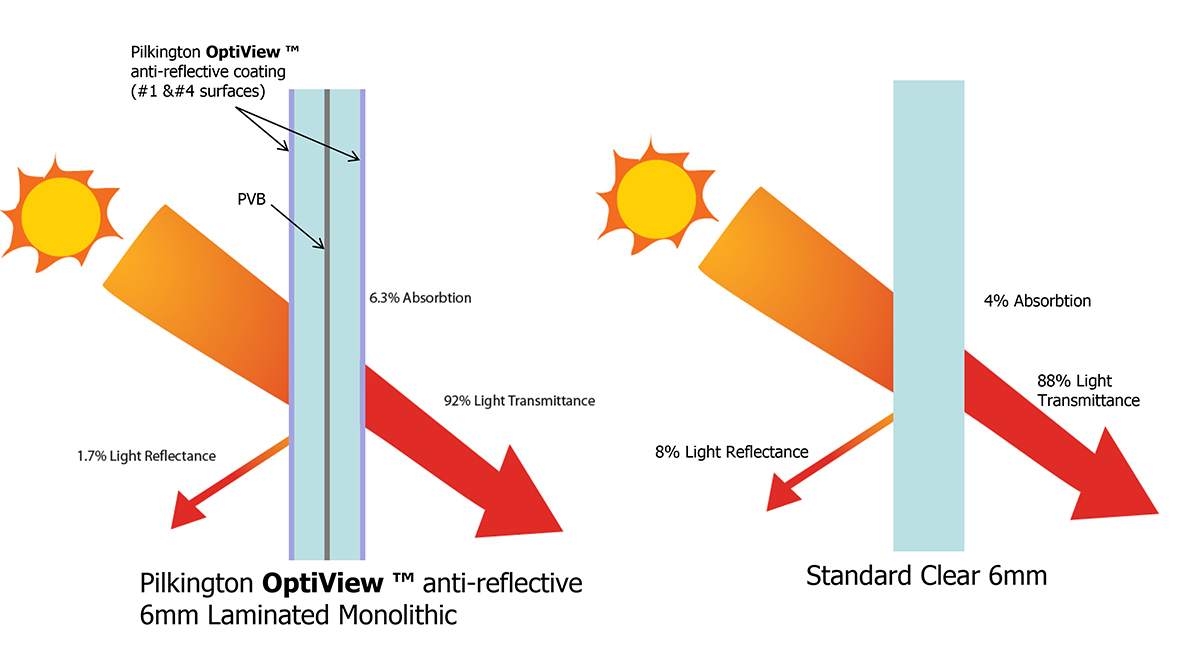

Seamless splicing technology minimizes the visible gaps between individual screens in a video wall. This is achieved by reducing the bezel width, resulting in a smooth and continuous image across the entire display. This technology enhances the visual experience by providing an uninterrupted and immersive viewing experience, which is particularly important for applications that require high precision and detailed visuals.

Comparing LCD Splicing Screens and LED Screens

LCD Splicing Screens:

Advantages:

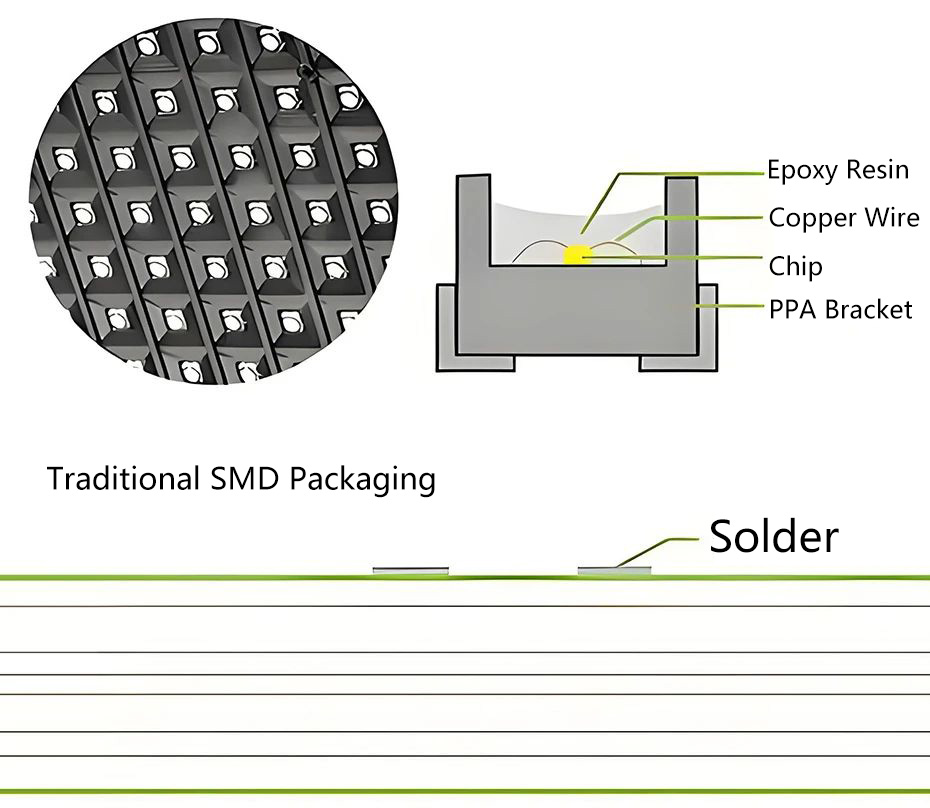

- Higher Resolution: LCD panels typically offer higher resolution, delivering clearer and more detailed images, which is essential for applications requiring precision and clarity.

- Color Accuracy: LCD screens are known for their superior color accuracy, making them ideal for environments where true-to-life color representation is critical, such as in control rooms and digital signage.

- Cost-Effective: Generally, LCD splicing screens are more affordable than their LED counterparts, making them a popular choice for budget-conscious projects.

Disadvantages:

- Bezel Width: Despite advancements in seamless splicing technology, LCD splicing screens still have thin bezels that may be slightly visible, potentially disrupting the seamless viewing experience.

- Limited Viewing Angles: LCD screens can suffer from reduced brightness and color accuracy when viewed from wider angles, which might be a limitation in some setups.

LED Screens:

Advantages:

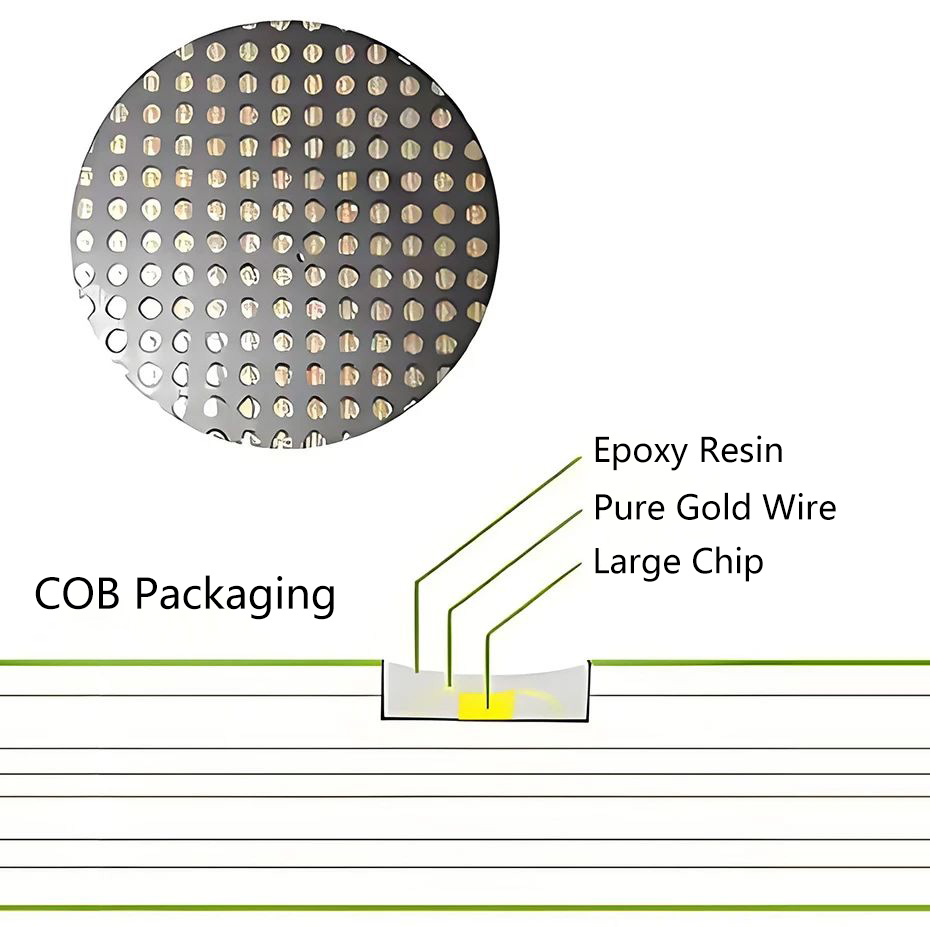

- True Seamlessness: LED screens can achieve true seamlessness with no visible gaps, providing a completely uninterrupted viewing experience, which is crucial for large-scale displays.

- Brightness and Contrast: LED displays offer higher brightness and better contrast ratios, making them suitable for outdoor and high-ambient light environments.

- Flexibility: LED panels are more flexible in terms of size and shape, allowing for creative and custom display configurations.

Disadvantages:

- Higher Cost: LED screens are generally more expensive, which can be a significant consideration for budget-sensitive projects.

- Power Consumption: LED screens typically consume more power, leading to higher operating costs over time.

How to Choose the Right Display for Your Application?

When deciding between an LCD splicing screen and an LED screen, consider the following factors:

- Budget: Determine your budget constraints and weigh the initial investment against long-term benefits and operational costs.

- Display Environment: Assess the installation environment. LED screens are better suited for outdoor and high-ambient light conditions, while LCD screens are ideal for indoor settings requiring high resolution and color accuracy.

- Content Requirements: Consider the type of content you'll be displaying. If your application demands seamless visuals, such as in a control room or large public display, an LED screen might be more suitable. For detailed images and color accuracy, an LCD splicing screen is preferable.

- Maintenance: Evaluate the maintenance requirements and operational costs of each option. LED screens may require more frequent maintenance and higher power consumption.

Conclusion

Choosing between an LCD splicing screen and an LED screen depends on various factors, including your budget, display environment, content requirements, and maintenance considerations. By understanding the strengths and weaknesses of each technology, you can make an informed decision that best suits your specific application needs. While LED screens offer true seamlessness and superior brightness, LCD splicing screens provide higher resolution, better color accuracy, and cost-effectiveness, making them a reliable and versatile choice for many applications.